One of Endeavor’s most versatile maintenance bases is located outside Knoxville, Tenn. (TYS). With a four-plane hangar and many specialties and project capabilities, this close-knit team is dedicated to maintenance excellence while helping inspire and cultivate the next generation of aircraft technicians.

Base Manager Jay McKinley has been at the helm of TYS since 2018 and oversees a team of 95. Jay takes a holistic approach when it comes to leading his base – if his employees are in a healthy mindset outside of work, they’ll have a better mindset at work.

“When you’re stressed about life and the future, you’re more prone to put others at risk, especially when you’re working on an airplane,” Jay said. “We work to make sure everyone is taken care of inside and outside of work.”

Jay also puts a strong emphasis on creating opportunities for individuals to help them achieve their long-term goals, whether that is working on sheet metal, interiors, or helping them gain the knowledge and skillset to work at a mainline hangar.

“If you’re coming out of A&P school, we’ll take the time to help develop you as an AMT, and Endeavor provides great opportunities to develop a career,” said Jay.

Each of Endeavor’s maintenance bases differs in their work and capabilities. Some are line maintenance only; others take on modifications or special projects in addition to their maintenance tasks. These are a few capabilities that make Knoxville unique.

INTERIORS

While every Endeavor base works on interior maintenance and upkeep, TYS has a dedicated interiors team. This team handles interior cosmetic upkeep, but their top priority is safety and peace of mind for customers. Their maintenance work includes seats, lights, tray tables, lavatories, and the cockpit.

“1,000 positives don’t outweigh a negative to a customer,” said Mike Hollis, Interiors. “The interior is the first thing they see, so having a presentable and acceptable interior for passengers is key. A plane helps reinforce to our passengers that our plane is safe and ready to fly.”

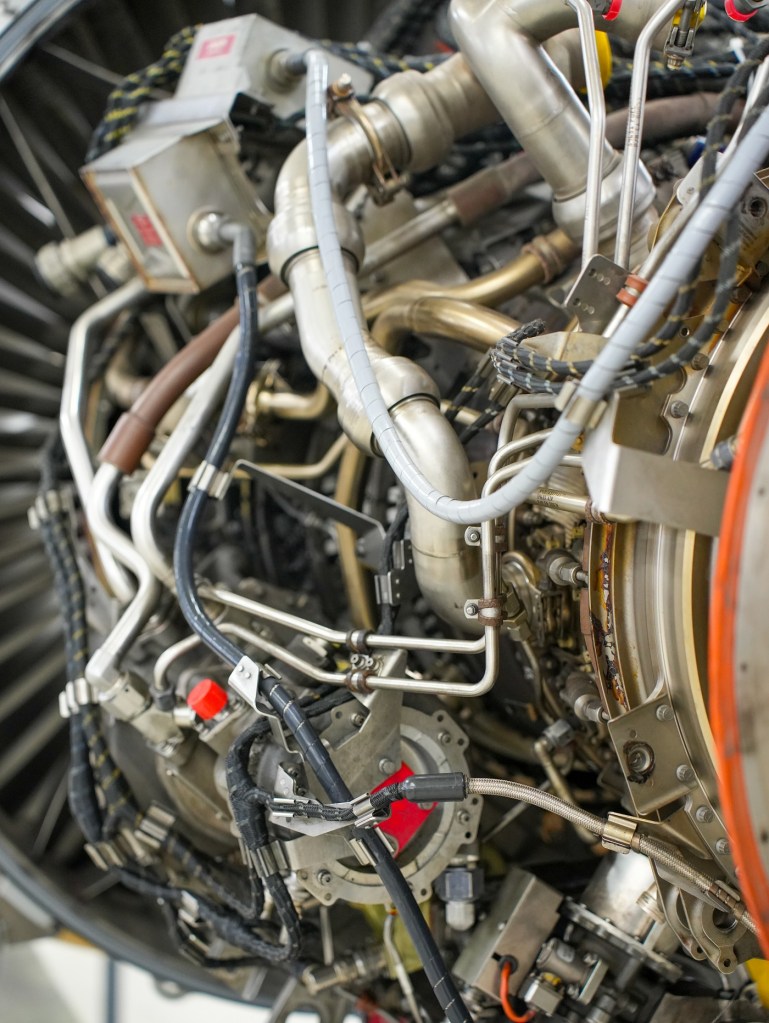

ENGINE SHOP

TYS is one of two Endeavor maintenance bases that currently operate an engine shop. TYS handles all repairs of the pins and most of the fan blades for the entire Endeavor system. The engine shop handles regular inspections and maintenance of the engines, engine builds, and will be tasked with engine replacements on the aircraft, too.

SHEET METAL

Sheet metal work is important as it repairs the outside of the aircraft, and TYS is one of the few bases for Endeavor that has the capabilities to execute sheet metal tasks.

The day shift refurbishes inlets and helps with the engine shop – working on pieces like the aft core and fairings. At night, the team repairs damage when the aircraft is in the hangar, working with the engineering team at Endeavor’s headquarters to get the aircraft back up and running as quickly and safely as possible.

SVL AND SCHEDULED MAINTENANCE

In addition to its scheduled maintenance work, TYS is often tasked with special projects called SVLs (Special Visit Line), like the digitization of the Quick Access Recorders (QARs). Nightly, Knoxville handles line and routine checks. While the work on each aircraft varies by day, tasks range from oil changes and tire changes to engine replacements. The base will also be tasked with handling A-checks when planes reach the 800-hour threshold.

COMMUNITY OUTREACH

Through Jay’s efforts, the base has built strong relationships with the local aviation community. The team has hosted Experimental Aviation Association (EAA) events and tours in their hangar, bringing in employees from the Air Traffic Control tower, Knoxville Airport Authority, Civil Air Patrol, and more to help inspire the next generation of aviation professionals.

The base has also worked with Pellissippi State Community College to gain support to start an A&P program at the school. In addition, TYS recently partnered with a local high school to allow a student to shadow and apprentice technicians while completing his senior year.

Want to learn more?

Take a 360° tour of Endeavor’s TYS maintenance base.